How opals are polished?

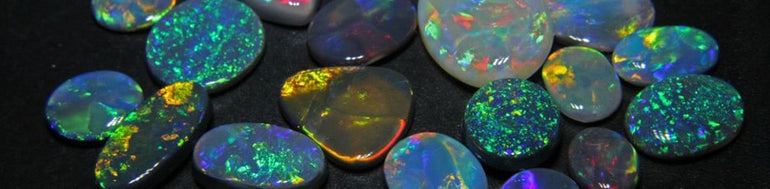

Unspeakable beauty is hidden within opals. They are magical, colorful, and brilliant. Their natural shape is unique and their very existence means a lot to us. However, we learned that we can get even more out from them, more light, more color, and more brilliance. For that reason they are being cut, polished, and shaped into a variety of forms – and only to make them look even livelier and more attractive.

Many stones, like emerald, aquamarine, and diamond are very beautiful in their natural form, and can be used as such. But, most of the opals need their shape and size to be adjusted for a very simple reason - rough specimens found in nature contain a number of impurities, cracks, and uneven color distribution.

Polishing is one of the oldest forms of fashioning precious opal. It gives the shine to the surface of the stone. After an opal is separated from the matrix and its fire is located, the cutter has to determine in which direction he’s going to proceed, and decide on opal’s future shape and form.

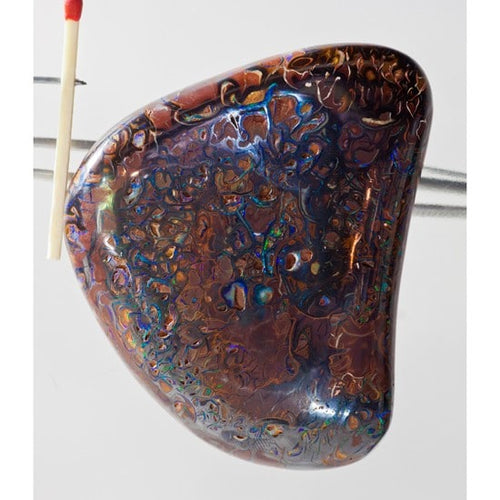

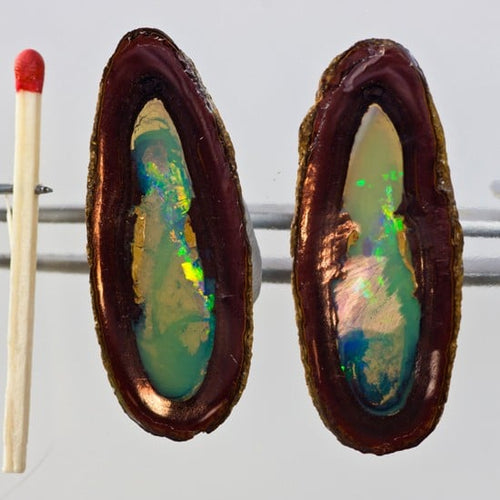

Then he’s rough shaping the stone. Australian opal is usually cut “en cabochon” with a smooth, rounded surface and highly polished domed top. This way the play of color is visible from all directions. The only exception is boulder opal which is shaped into free form. When opal is cut and shaped, it is time to give this beauty-to-be some polish. By this stage, the cutter has used the whole range of diamond wheels, but for the final polishing of an opal, since it is very soft and easily damaged, it is best to use flat lap felt wheel and Cerium Oxide mixed with water.

Prior to polishing, it is recommended to wash the stone, the machine and the equipment so that the dust and grit remains don’t scratch the stone’s surface. The opal stone is then attached onto a dop stick with some wax to facilitate handling.

After the felt polishing pad is mounted to the master lap and installed on the machine, it is time to wet it down. Because the felt pad needs to be damp, not soaked, cutters usually turn the machine on for a short period of time to eliminate sufficient water.

Next comes the ”charging” or loading the pad with the polishing powder. Opal cutters usually use a brush to apply small amounts of Cerium Oxide mixed with water to the pad. It is important not to use too much of the mixture because the excess powder can turn into tiny balls which will scratch the surface of opal.

During the process of polishing the lap has to be run at a faster speed, so rinsing the stone frequently is of the utmost importance. Otherwise, the opal may crack or burn due to friction. When polishing, the stone must be constantly rotated so it doesn’t overheat. From time to time, the cutter dries the opal to check the progress.

When the desired degree of shine and smoothness is achieved, opal can be removed from the dop stick and cleaned from the remaining wax. If the cutter is happy with the final look he will move on to the back of the stone which is cut flat.

The last thing that has to be done is to wipe the precious opal gem with a tissue or soft cloth. The rest is in the jewelers’ hands.

You may like: